The invention of the steam locomotive was pivotal in British history. Before railways were introduced, the only methods of transportation for heavy goods were via horse and cart on poorly maintained roads or on waterways.

The invention of the steam locomotive was pivotal in British history. Before railways were introduced, the only methods of transportation for heavy goods were via horse and cart on poorly maintained roads or on waterways.

Digital Welding is the integration of digital technology to improve efficiency and control in welding. New techniques, automation and equipment create better and more consistent welds with reduced waste.

Since the invention of computers in 1950, every aspect of our daily lives has been speeding towards digitalisation. From precision engineering to basic tasks like opening curtains, technology is being developed relentlessly to reduce manual involvement and increase efficiency. Our world is heavily impacted by digitalisation, and welding is no exception. The ancient welding technique is being improved and enhanced with digital processes like predictive maintenance, automation, and weld monitoring. In this blog, we’ll examine the role of digital technology in welding.

From heating metal over charcoal fires in the Bronze Age to robotics and cobots in 2024, welding processes, equipment, and theories constantly evolve. Technological advances have had a huge impact on welding in recent years. Let’s take a look at some of the most significant innovations in this age-old process.

Welding helmets are a critical piece of equipment for welders. Without them, the intense heat, flying sparks, UV rays and radiation would cause severe burns and irreparable damage to the eyes. Traditional welding masks and helmets are made from a non-flammable shield to protect the skin, with a darkened lens to protect welders’ eyes from the harmful light produced by the electric arc used to melt and join metals. The lens must be so dark that the welder can’t see anything until an arc is struck. In recent years, welding helmets have improved vastly through digitalisation. Augmented Reality helmets are a game changer in the world of welding. From within the helmet, a technician can view torch angle, welding parameters, work instructions and potential defects. Sensors detect the start of a weld and automatically adjust the lens accordingly. The introduction of Augmented Reality welding helmets has improved accuracy and safety and allowed less experienced users to repair welds successfully.

Laser welding is a growing area in digital welding. The process uses a high-energy laser beam to join materials. It is extremely precise and highly efficient. Laser welding is so exact it can also be used to restore imperfections in metal; only the area with imperfection is affected, meaning the integrity of the remaining part is maintained. Laser welding doesn’t heat metal as traditional welding does, so it won’t introduce impurities or alter the material’s structure in the same way. The process is so cool that the metal can be handled with bare hands as soon as it’s been repaired.

Laser welding is suitable for cast iron products, too. It can successfully create strong welds and reduce cracking, and it’s an excellent option for hard-to-reach areas. However, laser welding does have significant disadvantages. It has a high initial cost, making the process very expensive and simply not cost effective for many applications. It also has limited penetration and struggles to weld particularly thick materials, or large gaps. Laser welding cast iron is more suited to thin or delicate parts while gas fusion remains the leading repair method for automotive parts, marine components, including cylinder heads, and industrial machinery.

Robotic welding is a significant future trend in welding. Benefitting from artificial intelligence and machine learning, robotic arms perform welding tasks more efficiently and with increased precision. Each task is performed consistently, and even complex welds can be performed without human intervention, reducing the human error factor. This trend in welding is set to increase rapidly as robotic systems become smarter through machine learning.

The Internet of Things is a network of physical devices that can connect to the Internet and share data with other devices. Data analytics and the IoT are exciting developments in the welding industry, offering endless possibilities in terms of integration and control. Sensors can process real-time data on quality. Then, adjustments and improvements are automatically fed back to technicians. Multiple machines can work together, making complex industrial welding processes smoother and more efficient. This continuous monitoring and data collection vastly improves quality and consistency. Predictive maintenance schedules can also be deployed, reducing downtime and improving the lifespan of equipment.

For the welding industry, legacy processes and systems still dominate within the sector. But the outlook is promising as new innovations take hold.

With the current focus on environmental issues and the pressure to act responsibly, it’s good to know that many of these advancements in digital welding have a positive impact on sustainability: laser welding requires less energy; automation, robotics, and the Internet of Things are more efficient and produce less waste; and predictive maintenance improves the longevity of equipment. The future of welding is bright.

If you have a damaged cast iron item, contact the team at Cast Iron Welding Services for an informal discussion. Through years of dedicated service to the cast iron industry, we have perfected our gas fusion welding process. Thanks to our work on unique, diverse projects up and down the country, we have extensive knowledge regarding cast iron repairs.

Ornate grandeur and lavish decoration – that was the style among Victorians back in the day. During the mid to late 1800’s, the Gothic Revival heavily influenced architecture in the UK. This period of architecture played on medieval English styles, with decorative towers, finials, parapets and figurines featuring widely. The cost and availability of cast iron during Victorian times fuelled its popularity massively. This was the material of choice for Victorians, and it allowed them the freedom to create structures that were fashionable at the time. Its impressive castability made intricate detailing possible. And it was structurally capable, meaning these complex designs could be applied to buildings and infrastructure. Cast iron in Victorian architecture was a win-win.

The reign of Queen Victoria between 1837 and 1901 produced a period of opulent extravagance, which poured into architectural designs at the time. In fact, the architectural profession is primarily a Victorian creation; in 1834, the Institute of British Architects was born. At this time, architects were able to focus less on developing and surveying and more on style and design. Their designs were facilitated by the Industrial Revolution and the arrival of the railways. Suddenly, materials such as cast iron could be transported easily up and down the country, turning these elegant ideas into reality. Technical developments, such as iron-framed construction, benefitted from the new method of transportation and readily available materials.

Various historic styles inspired Victorian era architecture:

The Industrial Revolution was a period of revolution for cast iron. In the mid-18th century, Abraham Darby pioneered a new method of using coke to fuel huge blast furnaces. His method offered a significant step forward in the smelting of pig iron to produce cast. This was a turning point for cast iron production and availability. Gradually, towns up and down the country became industrial rather than farming communities; often, entire towns were purpose-built around their blast furnace.

Suddenly, this valuable alloy was available in large quantities, and it was cheaper than other building materials. The important properties of cast iron were something the Victorians made good use of…

It’s impressive castability and flowability in particular, made cast iron super popular with the Victorians. Decorative cast iron is found almost everywhere in Victorian era architecture. Look out for images of the impressive Crystal Palace building, a huge cast iron and glass structure that used some 4,500 tons of cast iron and was in fact only a temporary building used to house the Great Exhibition of 1851. The trend continued in America with the construction of the Capitol Dome building. Over eight million pounds of cast iron went into building this remarkable structure.

Closer to home, cast iron can be found nationwide in ornate railings, bridges, fountains, statues, staircases, paving and more. If you want to spot Victorian cast iron architecture, look out for decoratively elaborate detailing.

As Victorian architecture continues to age, time and effort should be invested to guarantee its integrity and preserve the history associated with these heritage items. Cast iron structures and decorative items made during the Victorian era often suffer from corrosion, mechanical stress, and environmental wear and tear, and the restoration process can be challenging. The damage usually requires structural repairs, using precise welding techniques to mend cracks, fractures, and erosion. Cosmetic restoration requires meticulous attention to detail, by hand painting and referencing historic archives to replicate the visual completely.

Victorian era architecture is brimming with elegance, opulence and historical influences. It offers a wealth of inspiration and knowledge for modern-day architects, designers and homeowners alike. Restoring cast iron heritage items keeps history alive and allows future generations to benefit from the aesthetics, prominence and memories of this important period in history.

If you have a cast iron heritage item in disrepair, contact the team at Cast Iron Welding Services for an informal discussion. We are experts in our field and we have extensive knowledge regarding heritage restoration, thanks to our work on unique, diverse projects up and down the country.

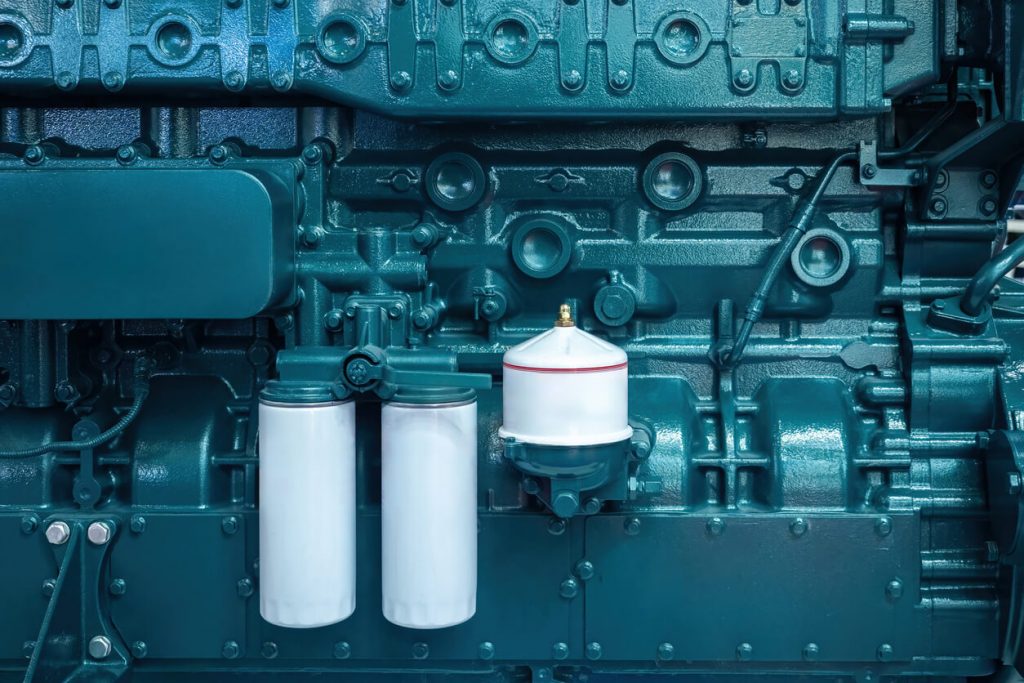

A cylinder head is part of the internal combustion engine. It is a critical and widely used component, produced to different specifications and applied in the automotive, locomotive, marine, engineering and aviation industries.

Cast iron has been around for a very long time! In China, archaeologists have discovered cast iron artefacts that originate from the 5th century BC. Indeed, cast iron was invented in China. It was first cast in moulds to make weapons, farm equipment and cooking pots.

Cast iron has many benefits. It has a relatively low melting point and offers excellent machinability and castability. It has good corrosive qualities and resistance to deformation and wear.

A cylinder head is a valuable piece of machinery. It forms an essential part of the internal combustion engine, and it has become vital in industrial, automotive, and marine applications. But how much does a cylinder head cost, and are there ways of reducing the cost?

A marine engine is the propulsion system used to power boats and ships. It is a specialised internal combustion engine built to withstand the elements and the harsh saltwater environment.

Bronze and cast iron are traditional materials that have been used for centuries to produce weapons, cooking vessels, parts for marine and locomotive vehicles, engineering structures, and decorative items like statues and architectural finishes.

If you are involved in the automotive, locomotive, marine, or aerospace industry—or indeed any application where an engine is used—you have probably encountered a flywheel. Flywheels, originally invented to power steam engines, have been used since the 1800s.

Cast iron has a long and varied history. The use of cast iron for agriculture, architecture and weapons can be traced back as early as the 5th century BC. And there are references to early high-temperature furnaces over 1000 years ago. Due to its prevalence and longevity, there are numerous examples of early cast iron manufacture. More recently, as engineering technical knowledge improved, cast iron has been used widely in the construction of bridges and structural supports in buildings.

Cast iron is made from pig iron, which is the product of melting iron ore in a blast furnace. Its beneficial properties, including excellent machinability, deformation resistance, and good fluidity/castability, have made it a staple in the production of machinery, pipes, and structural components.

It has immense compressive strength and is well suited to the stack and build construction process used in brick houses.

In 1925, two prototype semi-detached houses were constructed in the Brewery Fields Estate in Dudley and built entirely from cast iron panels. A second pair was built in 1927. This was a post-war experiment in the construction of prefabricated buildings.

The Industrial Revolution in Britain created huge advancements in the use of iron in construction.

The 18th Century saw significant developments in the iron smelting process, which led to mass production and put Great Britain at the forefront of the Industrial Revolution.

Abraham Darby is credited for his role in the Industrial Revolution. His craft as an ironmaster and foundryman led to him developing a new way to manufacture pig iron on a large scale. Previously, charcoal was used to power the blast furnaces, and large volumes of trees were felled to manufacture the charcoal. However, in the 1700’s wood became scarce following deforestation and the price of charcoal began to rise. In 1709 Darby created a method of smelting iron ore with coke. This presented a major step forward as coal was a huge natural resource. His method was cheaper, more efficient, more environmentally friendly and allowed for the production of iron on a large scale.

As Britain celebrated its triumph in the First World War, a new challenge emerged. There was a severe housing shortage, and pre-war slum housing was an embarrassment to the government. So, in 1918, the government introduced its “Homes for Heroes” campaign. Unfortunately, traditional raw materials for construction were scarce at the time, so local planners needed to look at alternative materials. Such was the abundance and versatility of cast iron that an experimental development in the West Midlands was trialled.

The houses did not require a skilled workforce, which was in short supply after the war, and the iron industry’s spare capacity could be utilised. The houses were constructed from 600 panels of precast iron, which could be produced off-site and shipped within a week. Construction took place by bolting the panels together and took 4 men 8 days to complete. The panels were designed with a patented flange that was used in assembly and created a watertight seal.

The prototype was easily scalable and suited to mass production – it seemed a sensible solution all round.

In the Brewery Fields Estate, Dudley, four semi-detached houses were built with walls constructed entirely of cast iron. The interior walls were lined with asbestos sheets and the cavities filled with waste wool. The exterior was covered in cement-based enamel and painted white to deflect the heat and protect against corrosion.

The project was experimental and short-lived, as the houses proved costly to build. Brick became more readily available, and as a brick house cost £400 to build, this was a fraction of the cost of a cast iron house, at £1000. The rent charged on a cast house was around 10 – 12 shillings per week, which was too much for most ordinary workers.

In nearby Derby, around post-war 200 council properties were constructed from cast iron. They were nicknamed ‘Derby Tanks Houses’. Most remain occupied to this day. The houses are currently part of a major upgrade by Derby City Council, as residents have complained of high energy bills. The renovation has its challenges, however, as contractors must establish safe methods of working without disturbing the asbestos-lined walls. The upgrade of some of the houses was completed in 2022, with the next phase of 150 houses approved for renovation in 2023. Residents have benefited from external solid wall insulation, new windows, doors and lighting which has led to significant energy cost savings.

A few hundred cast iron houses were constructed at Thorncliffe. They used pre-fabricated cast iron panels, and the interiors were constructed using traditional wood.

Many other local councils adopted the prototype cast iron house plan to solve their housing crisis, as new modular methods of construction were explored.

Two of the original cast iron houses from Dudley have been moved to the Black Country Living Museum and renovated as part of the Forging Ahead project. Visitors to the museum can visit the 1940 house and the 1968 house to experience everyday life in wartime Dudley.

When it comes to metalworking, cast iron holds a special place. Its durability, versatility, and timeless appeal make it a sought-after material across various industries.

There are a few reasons why someone might want to weld cast iron to steel, whether for structural, decorative, or other purposes. Fortunately, there are methods available to effectively join these two metals.

Invented in China during the 5th century BC, cast iron was initially utilised for a variety of purposes, including the crafting of ploughshares, pots, weapons, and pagodas by pouring it into moulds.

Cast iron is a versatile material with a rich history in various industries, known for its strength, durability, and unique properties.

If you have ever worked with or shopped around for metal you may have heard the term ferrous and non-ferrous, but which term is correct when it comes to cast iron?

Cast Iron is often a misunderstood metal, there are plenty of misconceptions about what you can and cannot do with cast iron, most commonly around welding cast iron.

Located at the top of the engine block, the cylinder head is a critical component that plays a vital role in the function of a combustion engine. It is an essential engine part, used to power vehicles, locomotives and marine vessels.

Rust forms when iron reacts with oxygen and water causing that familiar orange and brown flaking also known as iron oxide.

Cast Iron is a fantastic material that has been used for years and is known for its excellent strength and durability.

Induction cooking is different to gas and electric hobs. It works by relying on magnetic fields to heat your cookware, which means your pan needs to have conductive, ferrous metals for effective heat transfer.

To understand magnetism, it’s important to understand the structure of a material. All substances are composed of atoms, each with a nucleus at its core. Orbiting around the nucleus are electrons, which carry an electric charge. In certain materials, electrons spin in various directions, resulting in a balanced atom with minimal magnetism. Examples of these materials include paper and cloth.

Discover the impressive capabilities of Wartsila’s largest marine engine and its impact on maritime power.

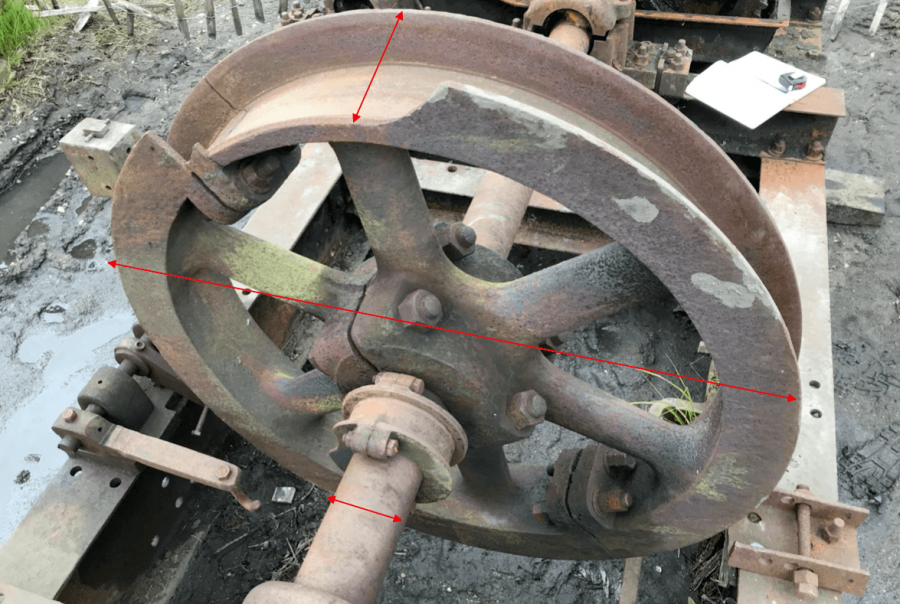

Fig 1. Drop Hammer Gantry (inverted) showing X2No. Flywheels in need of repair (#1 & #2)

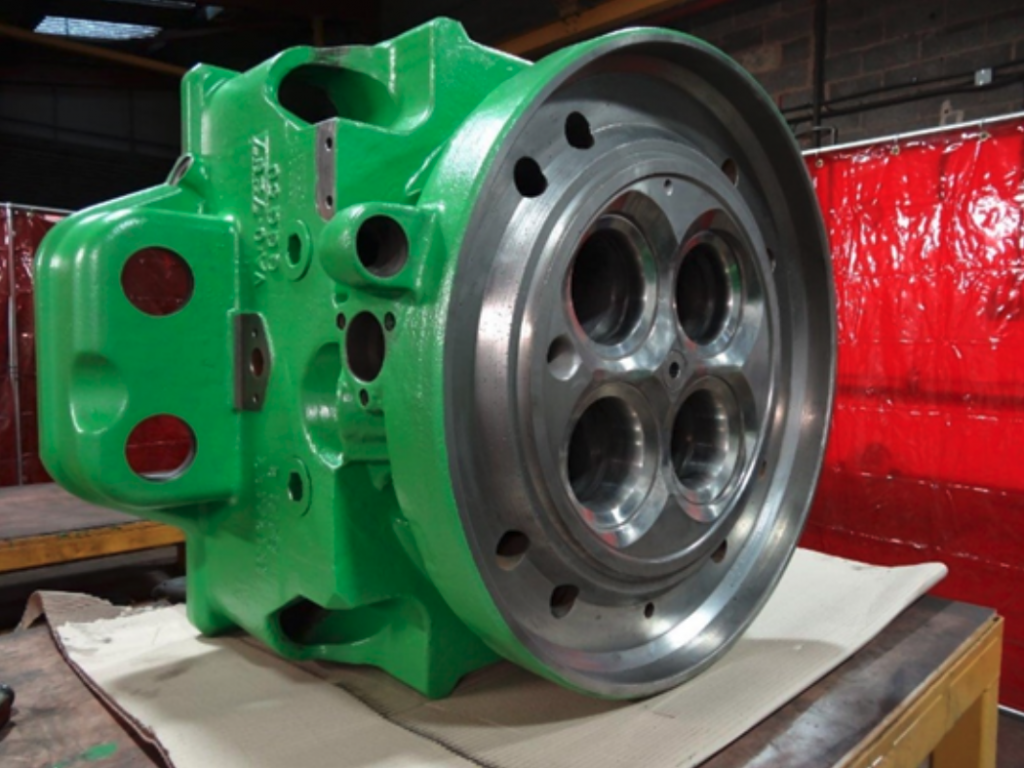

As part of the Black Country Living Museum’s (BCLM) ambitious Forging Ahead development project an Industrial Quarter will be created to reflect the region’s rich heritage in manufacturing.

A key part of this will be the recreation of Smith Edge Tools – a Drop Forge from Roway Lane, Oldbury which was most famous for manufacturing hammers up to 28lb.

BCLM collected the Drop Forge equipment from the site when it closed in the early 2000s including the gantry and motorised mechanism, stantions, anvil bases and tups (hammers) with the aspiration that these could be installed in a working forge at the museum.

The equipment has since been stored in an external compound awaiting restoration.

Forging Ahead has created the opportunity to repurpose the equipment which has recently been recovered from the compound and reviewed to understand what repair work is necessary.

It is apparent that X2No. Flywheels on the main drive shaft are in need of repair – being cracked and in some cases missing sections of the outer rim.

The flywheels are comprised of two semi-circular sections bolted together over the main shaft.

BCLM are seeking to have the flywheels repaired in readiness for the installation of the equipment in the recreated Smith Edge Tools.

Fig 2. Flywheel #1

2 section flywheel (bolted together)

< 104cm diameter >

Width (total): 14.5cm approx.

Inner rim: 12cm approx.

Rim: 1cm approx. Drive shaft measures

32cm circumference (approx.)

Fig 2a. Flywheel #1

DETAIL of damage

Fig 2b. Flywheel #1

DETAIL of damage

Fig 3. Flywheel #2

2 section flywheel (bolted together)

< 104cm diameter >

Width (total): 11.7cm approx.

Inner rim: 8.6cm approx.

Rim: 1.4cm approx.

Drive shaft measures 28cm circumference (approx.)

Fig 3a. Flywheel #2

DETAIL of damage

Fig 3b. Flywheel #2

DETAIL of damage

At Cast Iron Welding Services, we recently performed expert restoration on a Victorian-era handrail in Lancashire. The old Victorian handrail was located at the top of a stone canal bridge and, as well as the wear and tear making the handrail an eyesore, it was posing a health risk to members of the public enjoying the canal path.

These Victorian rails have been a part of the aesthetic of the area for over 100 years and, as a result, are an important part of the heritage of Lancashire. At Cast Iron Welding Services, we take heritage seriously. We were founded in 1947, so all of our expert welding team know a thing or two about the importance of history.

The only problem with history is that it is prone to wearing, rusting and fading away. At Cast Iron Welding Services, we have the expertise and passion for ensuring that stunning pieces of cast iron history last long into the future. Our heritage restoration services have ensured that many historic landmarks maintain their unique beauty and sense of grandeur.

We have developed our gas fusion welding process over many years of dedication. Because of that, we were confident that we could get this Victorian handrail back to its very best. When we arrived on site, the handrail looked rusted and damaged and was barely recognisable as the striking cast iron structure that it once was.

The handrail was completely broken away from the stone wall that supports it. Many of the cast iron support pillars were also broken. With this area being incredibly beautiful and appealing to walkers, joggers and cyclists, safety was just as important as appearance with this restoration job.

We took great care to work this piece of historic metal free so that no further damage was done. Once we had completely removed all the remaining rails from the stonework and gathered all the broken pieces from the footpath below, we brought them back to Coalville for the restoration work to start.

Our expert team of engineers then painstakingly restored the damaged and rusted cast iron handrail back to its former glory. Seeing the beauty of the past emerge from the rusted wreckage of the present is always a satisfying experience. And this was no different, with sturdy and historic Victorian cast iron soon emerging from beneath the rust.

Once completely restored, we painted the iron with care and dedication. With the handrail finally looking at its best, we installed it back in its home for yet another happy client. We’re always incredibly proud of our work, but when it comes to restoring a piece of history back to its former glory, we could not be happier.

So much history and heritage have been crafted from cast iron. So, at Cast Iron Welding Services, we have made it our mission to ensure this history is with us for many years to come. Throughout history cast iron has been used to create stunning ornamental pieces as well as robust structures.

Unfortunately, as these cast iron creations have been battered by time and the elements, many have worn away and become a shadow of their former selves. The same can be said for classic car parts and other vintage products made of cast iron. Our team of expert engineers has honed the process of keeping history alive to a fine art. With restorations of vintage cars, historic structures and more, we are a one-stop shop for cast iron restoration.

Over the years we’ve developed a reputation for only the best restoration work. So much so that we were recently seen on TV helping Richard Hammond restore a classic car for his new show. We have also worked with the National Trust and other organisations dedicated to keeping historic landscapes looking at their inspirational best.

If you have a vintage car or piece of classic cast iron that needs professional restoration, contact Cast Iron Welding Services today. Our dedicated team will be able to offer expert advice and quotes for any type of cast iron restoration and repair. For more information on how Cast Iron Welding Services can help you, request a brochure.