Discover the impressive capabilities of Wartsila’s largest marine engine and its impact on maritime power.

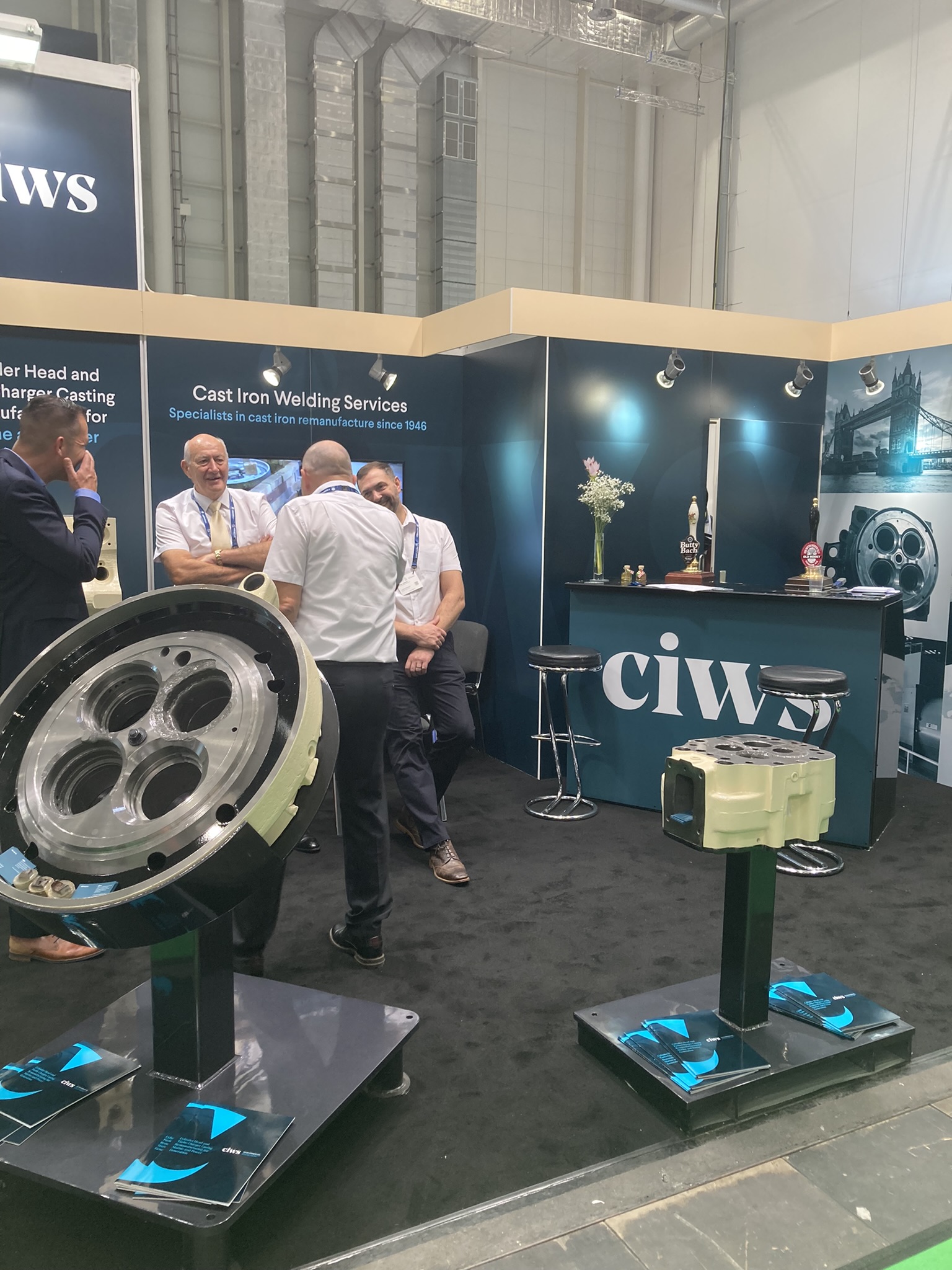

🚢👬 👭 Successful visit to SMM Hamburg for the Cast Iron Welding Services team with lots of new business. We were extremely happy with the build and design of the stand at this year’s SMM Hamburg show. It’s been 4 long years since we were last in Hamburg, and it was great to see so many old faces but also some new ones. There is nothing better than meeting people face to face.

😓🙏🏻Overcoming issues with transport logistics. We were a little nervous about managing to get everything to the show in time as this was also not only the first major European exhibition Cast Iron Welding Services took part in after COVID but also logistically after Brexit. We were able to use the authorised logistics company for the show to transport our main exhibits but unfortunately, they could not help with the British ale Cast Iron Welding Services has for the last few years taken for visitors to sample, which I am sure you can imagine is always very well received.

✔️🍻Our exhibition guests were some of the happiest in Hamburg. We finally found a logistics company Eurosprint who handled the delivery of our British ale for us and also a number of other people who helped along the way we managed to once again offer our visitors a pint of fine British ale

😊 🍺 💯💪There are few occasions where we will accept defeat but this one could have been one of those occasions, but with the perseverance and determination of our amazing team and everyone involved we adapt throughout our business. The ale was flowing! Thank you to all involved.

Marie Palmer‘s Video Transcript as part of the Directors Diaries:

“Hi everyone, I wanted to give you an update on what we’ve been up to in the last few weeks. So the last time I posted I talked about the SMM Hamburg maritime event and the preparations for our exhibition. So I was in the process of making sure the stand build and all the exhibition pieces had arrived on time. I can safely say everything turned out really well, I was very happy with the stand design and also the British ale managed to get there ok. I’m sure a lot of people that visited our stand enjoyed that just as much as our Cast Iron Welding services team did. It was great we had people from our Mexico facility which was great for them to catch up with lots of existing customers, suppliers and friends. We made lots of new friends and contacts too. It was a really good week with lots of positive opportunities made even more special as we’d not been there for 4 years due to COVID. It was great just to see everybody back to where they should be. We look forward to seeing what the next few weeks bring”

Cast Iron Welding Services are looking forward to taking receipt of our first cylinder head repair from New Zealand for remanufacture, it just demonstrates that even though the cylinder head is travelling that distance it still makes it cost effective for the customer.

From an environmental prospective we factored in our circular economy calculations, a cylinder head travelling from the other side of the world and we still had a significant carbon reduction. Not only are we saving the customer money we are helping them to reduce their carbon footprint with cylinder head repairs.

Marie Palmer‘s Video Transcript as part of the Directors Diaries:

“Hi everyone, we’ve been very busy again. I wanted to talk today about the confirmation for the latest arrival we’ve had for a cylinder head repair coming all the way from New Zealand. I’m really pleased about this one as it just demonstrates and reinforces we’re still cost effective with a customer having to send a repair to the other side of the world. The team here in the cast iron welding repair shop Leicester UK are really excited to get this processed before returning it to the customer efficiently fully repaired. We should see many more of these from that region, we have fantastic relationships with our friends and customers in New Zealand. We’re always talking about carbon emissions and carbon footprint, obviously when we carried our our Cylinder Head Repair life cycle assessment we wanted to ensure we’d included all the different scenarios and we did factor in a cylinder head coming from the other side of the world which means the results from that report do allow for this and are highly accurate. Not only is it cost effective for the customer but it’s also helping to reduce the carbon footprint within the cylinder head repair industry. I look forward to catching up with you all again soon. “

© 2024 Cast Iron Welding Services. | Privacy Policy | HTML Sitemap | XML Sitemap